Accademia Riaci

Student Reports

Read all class reports from our students!

Lara Blevi

Nationality: South-African

Course: Shoe Making

Program: One-Year Atelier Course

Period: Sept 5, 2016-April 25, 2017

She knew instantly that she would love to study further and learn more about shoes and decided to come to Firenze, Italy, the most famous city to learn more of leather art and shoes! She found Accademia Riaci and knew that the shoe making course that they had to offer was exactly was she was looking for.

Here she wishes to learn the highest level of shoe making techniques and to be able to follow her dream to become a designer with the knowledge of not only fashion, but also the art of shoe and handbag design.

南アフリカでファッションデザインの文学士号を取得後、ファッション業界で目指す方向を定めるためにもっと学びを深めたいと思いました。企業インターンを経験した際には、外国製の皮革を使用したカバン制作とデザインを学びました。

すぐに靴制作を学びたいと思うようになり、靴制作や革工芸を学べる世界で最も有名な都市・フィレンツェ行きを決意。検討の結果、自分が探し求めていた内容の靴制作コースを提供するアカデミアリアチへの入学を決めました。

ここで最高レベルの靴制作技術を身につけ、ファッションのみならず靴やカバンの知識も兼ね備えたデザイナーになることが夢です。

Dec. 15, 2016 | Posted in Reports, Shoemaking , Student Reporter | Tags:Lara Blevi, ShoemakingReporter: Lara Blevi | Course: Shoemaking

Shoe Making 13-One Year Course 2016

The second last week before the holidays and we are definitely not slowing down. This was quite a labor-intensive week as we all prepared our insoles for the Goodyear technique. The proses takes a lot of time, strength and focus as you need to carve out two channels on the bottom of the sole and also make holes through them to be able to stich through with the hand-sewing needles.

クリスマスまで2週間を切り、クラス内は熱気で溢れています。今週はグッドイヤー製法の中底を作るため、多くの作業を行いました。底側に2本の溝を掘り手縫い針用の穴を開けるこの工程は、時間と力と集中力を要します。

Prof Angelo explaining to the class how to start the insole for the Goodyear technique.

グッドイヤー製法の中底の作り方を説明するアンジェロ先生。

After the insole as been set on the last overnight to dry, the needles are removed and the excess leather is cut of from the sides of the last. After that you end up with a perfectly shaped insole for the last of your shoe.

木型(ラスト)に中底をセットし一晩乾かしたら釘を取り除き、木型からはみ出している余分な革を切り落とします。これで自分の木型にぴったりと合った中底の完成です。

Here you can see the sole on the last before the excess has been cut of and what the sole is meant to look like after the whole process of carving the channels for the Goodyear is completed.

右側が余分な皮を切り落とす前の、左側が切り落とした後の中底です。溝はこのような感じになります。

You can also draw the lines of the channels on the sole to make it easier to cut straight and to make sure that the channels ends up even.

曲がったりずれたりせずに掘れるように溝の下描きをして作業することもできます。

Joanne working her way through the whole process and trying not the cut herself. It takes a lot of focus to work with the knife and to make sure that your fingers are never in the wrong direction while cutting.

手を切らないように気を付けながら作業をしていたジョアン。刃物を扱うのでかなり集中しなければならず、決して間違った方向に指を置かないよう細心の注意が必要です。

The uppers of the shoes that I am working on for my boyfriend. This is just before I started the lasting process after I finished my insoles.

自分の彼氏のために作っている靴のアッパー部分です。中底のセットを終えた木型にかぶせただけの状態です。

Bernardo helped me with the pre-lasting of the shoe, as the leather that I am working on is pretty thick and difficult to mount. First the front of the shoe is roughly shaped and then the back heel end is lasted with small needles. After the back is complete only the front toe lining is lasted and then the reinforcement for the toe is placed in between the upper and the lining of the shoe.

靴の革が厚くて扱いにくかったので、アシスタントのベルナルドが吊り込み作業を手伝ってくれました。最初に靴のつま先側を大体の感じで形作り、次にかかと側を小さな釘で留めていきます。その後つま先側のライニング(裏張り)を吊り込み、つま先に補強材を入れたらその上からアッパーを吊り込みます。

During the lasting process it is very important to check the upper of the shoe for any imperfections and creases.

最後にアッパーに歪みやシワが寄っていないかしっかり確認するのが大切です。

The beautifully lit up Christmas tree outside of the Duomo. Florence is becoming so busy as everyone is doing their Christmas shopping and enjoying all the markets and live music in the streets.

ドゥオーモの前に飾られているクリスマスツリー。ライトアップが綺麗です。フィレンツェはクリスマスの買い物をしたり、市場巡りやストリートミュージシャンの演奏を楽しむ人々で賑わいを増してきました。

This weekend we also celebrated Andrea’s 21st birthday and we all went to Wasabi for all-you-can-eat sushi dinner.

週末はアンドレアの21回目の誕生日だったので、みんなで「ワサビ」という食べ放題のお寿司屋さんでお祝いをしました。

Gelato Internship Course (#2) – K

(2月3日)

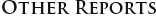

今日は画像を使ってイタリア語レッスン。レッスンの後は、クラスメイトと散策兼ねてメルカート…

Language:

Reporter: K

Course:

Internship

Gelato Internship Course (#1) – K

(1日目)

いよいよ留学生活スタート。時差でイタリア時間4時半起床。前日の23時到着で疲れているはずが…

Language:

Reporter: K

Course:

Internship

Bag Making Summer Course (#16) – Yang Guk HONG

The production of the second bag has started.

This …

Language:

Reporter: Yang Guk HONG

Course:

Bag Making & Leather Arts

At Accademia Riaci, we are recruiting Course Reporters from our students. The students who are chosen to become Course Reporters are given 10 % of the tuition as their scholarship fee.

The Reporters who have submitted excellent reports will have his or her profile posted on our school website for the next 5 years as an alumnae and will be able to connect with their business chancesafter their graduation.