Accademia Riaci

Student Reports

Read all class reports from our students!

Lara Blevi

Nationality: South-African

Course: Shoe Making

Program: One-Year Atelier Course

Period: Sept 5, 2016-April 25, 2017

She knew instantly that she would love to study further and learn more about shoes and decided to come to Firenze, Italy, the most famous city to learn more of leather art and shoes! She found Accademia Riaci and knew that the shoe making course that they had to offer was exactly was she was looking for.

Here she wishes to learn the highest level of shoe making techniques and to be able to follow her dream to become a designer with the knowledge of not only fashion, but also the art of shoe and handbag design.

南アフリカでファッションデザインの文学士号を取得後、ファッション業界で目指す方向を定めるためにもっと学びを深めたいと思いました。企業インターンを経験した際には、外国製の皮革を使用したカバン制作とデザインを学びました。

すぐに靴制作を学びたいと思うようになり、靴制作や革工芸を学べる世界で最も有名な都市・フィレンツェ行きを決意。検討の結果、自分が探し求めていた内容の靴制作コースを提供するアカデミアリアチへの入学を決めました。

ここで最高レベルの靴制作技術を身につけ、ファッションのみならず靴やカバンの知識も兼ね備えたデザイナーになることが夢です。

Oct. 04, 2016 | Posted in Reports, Shoemaking , Student Reporter | Tags:Lara Blevi, ShoemakingReporter: Lara Blevi | Course: Shoemaking

Shoe Making 4-One Year Course 2016

On Saturday we all had the privilege to visit the Museo del Tessuto in Prato. We traveled there early the morning by train and had an amazing guided tour through the museum with a translator. We learnt all about the history of textiles and fashion, saw amazing historic clothing pieces, were taught about new eco innovations to create textiles, and where also able to see beautiful prints inspired by art.

After the museum we decided to do some sight seeing in Prato. We had lunch next to the magnificent medieval Castello dell’ Imperatore and walked around through the town to experienced the stunning Prato Duomo.

At school during this week we continued our Décolleté shoe by completing the sole of the shoe as well as the heel. We also had the exciting opportunity to travel to the shoe last factory, Formificio Romagnolo, on Wednesday. We were all able to choose lasts to our preferences and size. I ordered myself three pairs of plastic lasts including a pair for boots, a pair for heels and also a pair to make classic shoes from.

Gorgeous hand embroidered wedding gowns we were able to see at the museo del Tessuto, dating back to the late 1800’s including the shoes that was worn on the day of the wedding. It was said that the around three to four pairs of shoes would be worn during the course of the wedding day as this represented wealth. Wealth was also expressed by the intricate hand embroidered details on the dress.

It was really fun to be ale to feel all the different textures that can be created by the different finished that could be applied to a textile. It also helps to understand the different techniques better.

Me standing in front of the historic Duomo of Prato during our little excursion through the town after visiting museo del Tessuto.

Here Angelo is showing us how to shape an already made sole to the shape of your last. First the sole must be attached to the shoe last at the heel, middle and front, and then the shaping will take place.

When making a Chanel Décolleté, the back of the heel will be exposed. This means that you need to create a special lining on the sole of the shoe to round it of neatly as this part will be exposed.

After adding in the reinforcement to the heel of the shoe, you will start the pre lasting process by using different size needles and hammering them down to shape the bottom of the shoe. This is quite a process and needs some time and focus to do. After this is done the reinforcement of the front of the shoe is added.

The front reinforcement is heated up with this special machine to melt the glue on the material and make it flexible to be able to shape on the front of the shoe. It is then placed in between the lining and the upper and shaped around the toe of the shoe.

After choosing your preferred heel for your shoe and making sure that it fits the height of the shoe last design, the pattern for the leather is created. This is done by placing the heel on the paper and tracing it all around. The leather is then cut out, shaped and glued on to the plastic heel, and then rounded of around the edges.

Our Décolleté shoes as far as we got to this week. All that still needs to be done is the insole of the shoe and the sole coverage at the bottom of the shoe.

The beautiful Arno River that runs through Florence on Friday on our way to the The Brancacci Chapel for our art visit.

Gelato Internship Course (#2) – K

(2月3日)

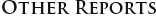

今日は画像を使ってイタリア語レッスン。レッスンの後は、クラスメイトと散策兼ねてメルカート…

Language:

Reporter: K

Course:

Internship

Gelato Internship Course (#1) – K

(1日目)

いよいよ留学生活スタート。時差でイタリア時間4時半起床。前日の23時到着で疲れているはずが…

Language:

Reporter: K

Course:

Internship

Bag Making Summer Course (#16) – Yang Guk HONG

The production of the second bag has started.

This …

Language:

Reporter: Yang Guk HONG

Course:

Bag Making & Leather Arts

At Accademia Riaci, we are recruiting Course Reporters from our students. The students who are chosen to become Course Reporters are given 10 % of the tuition as their scholarship fee.

The Reporters who have submitted excellent reports will have his or her profile posted on our school website for the next 5 years as an alumnae and will be able to connect with their business chancesafter their graduation.